Having LPG on board increases the chances of a life-threatening incident, so it makes sense to ensure your gas system is installed and maintained to the highest standard. Duncan Kent reports

Earlier this year, the UK’s largest supplier of portable LPG cylinders, Calor, expressed its intention to discontinue its very popular 3.9kg propane and 4.5kg butane cylinders. However, after much pleading by user groups throughout the country it has now agreed to phase them out more gradually, allowing cylinders that remain in good condition to be refilled for a while longer. It suggests users upgrade to its 7kg bottle. Unfortunately, apart from being too big to fit most boat gas lockers, this will also mean more expense when buying the larger cylinder and regulator to go with it.

There are a few voices in online boating groups suggesting you simply refill your existing 3.9/4.5kg bottles from larger cylinders using a cheap decanting kit. However,

self-refilling is against the law and can be extremely dangerous.

The LPG cylinders remain the property of the suppliers, who are the only authorities approved to refill them. The task is carried out under strict controls, thereby ensuring total safety for both its own staff and the end user.

Commonly available alternatives to Calor are Flogas and Campingaz, although their sizes don’t match exactly, and the latter is expensive in the UK.

The most popular gas bottle sizes are being phased out

Butane and propane

The two types of Liquid Petroleum Gas (LPG) available in portable cylinders and suited for use on a boat are butane and propane. The former frequently comes in blue cylinders and is the most common gas used on boats. It has a higher calorific value than propane and burns more efficiently, but it operates at a lower pressure (28mb) than propane (37mb), so their regulators are not interchangeable.

Propane cylinders are more commonly orange in colour and are often used by long-term cruisers as they are available in larger sizes and can be stored on deck without freezing. It’s essential to select the correct regulator to suit the type and capacity of LPG and cylinder you intend to use.

Modern technology has made the use of LPG onboard much safer than in the past. The elimination of pilot flames and devices such as flame failure detectors fitted to cookers and heaters has greatly reduced the risk of gas escape.

That said, butane and propane are heavier than air, so when it does leak it sinks and collects in the lowest point of the boat, the bilges. For this reason, it’s important to have a manual bilge pump even if you also have an electric one, as activating the latter in the event of a gas leak could cause an explosion.

There are strict rules in most countries governing the installation and maintenance of gas systems on a boat and these should always be adhered to if making any changes to the original system or reinstalling from scratch.

Gas lockers must be vented overboard and never used to store other items

Gas lockers

A safe marine gas installation starts with the gas cylinder storage locker, which must be vented overboard and not simply into a drained cockpit (as was common on many boats from the 1960s-1980s). The vent/drainpipe must be at least 19mm in diameter and should be taken from the lowest point in the locker.

It should be led directly to an open hull skin fitting (no seacocks or valves) and should exit well above sea level. The gas compartment’s lid should also be sealed in the event the drain becomes blocked and gas collects in the locker itself. This seal also helps keep water and debris out.

Older boats rarely had dedicated gas lockers, but there are numerous GRP inserts available that can be retrofitted into a cockpit locker or they can be custom made. Annoyingly, they are often sized to only hold a single cylinder, meaning any spares have to be stowed securely elsewhere in the boat. Unconnected cylinders rarely leak, though, so spares don’t necessarily need to be stored in a vented locker, although it’s better to be safe than sorry.

Note that LPG cylinders must always be stowed upright or you risk liquid gas running down the pipe, causing a dangerous flareup at the appliance.

Finally, nothing else must be stowed in the gas locker in case movement dislodges an item, which damages the pipe or cylinder, or blocks the drain.

It’s vital gas systems are checked regularly for any possible faults

Maintenance

Although mandatory for inland waterways craft, regulated by the UK Boat Safety Scheme (BSS), there is, surprisingly, no current UK-wide legal requirement for privately owned, sea-going cruising yachts under 24m to abide by the EU’s Recreational Craft Directive (RCD), or the UK’s equivalent (RCR).

That said, it can only be sensible to have your gas system checked regularly for its adherence to the latest safety regulations and to ensure there are no dangerous areas of wear in your system, such as out of date hoses or rusty hose clips.

You can install your own gas system — but it must be tested by a qualified gas engineer before use

Installation

It is perfectly acceptable, and indeed legal, to carry out the gas system installation on a boat yourself, provided you have a Gas Safe qualified engineer to inspect and pressure test it before you turn it on for the first time.

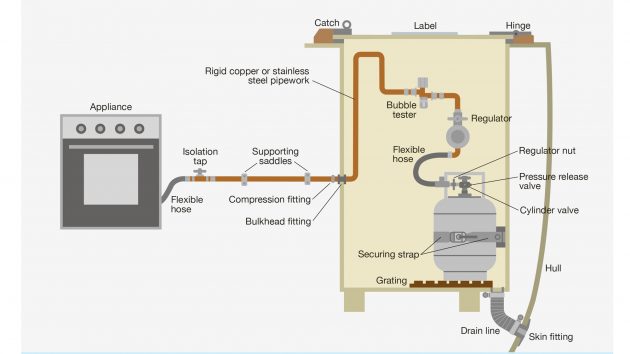

As much as possible, gas should be run through rigid copper pipe (usually 8mm or 3/8in diameter), all the way from the regulator to within 1m of the appliance. When penetrating the gas bottle locker, a proper bulkhead compression fitting should be used to keep the locker gas-tight. It will also provide a tail fitting for connection to the flexible hose from the regulator.

Requirements

The appliance end of the pipe should be terminated with an isolation tap, from which a short length (<1m) of correctly rated (BS3212/2) flexible, armoured hose, connects directly to the appliance. Note that all flexible gas hose is date-stamped and should be replaced every five years, or earlier if any wear or damage is visible. Any joins or connections must be done using the relevant compression joints with copper olives, not soldered or push-fit types.

No jointing compounds or PTFE tape sealants must be used in making the joints. The pipe must also be supported at regular intervals, usually 150-200mm, along its run. More support may be needed on corners and through bulkheads, and the latter should be protected from chafing, either by a grommet or by wrapping plastic hose around the copper pipe.

Using the correct tools, such as proper pipe benders and cutters, will avoid the risks of cracking the pipe or making poor joints that might leak. It’s worth using a marine-rated regulator too, as the typical camping device will not last long in a salty marine environment.

Under the gas installation regulations for modern yachts, it is mandatory to provide a manual shut-off valve near the appliance. However, I prefer to have the additional security of a remotely switched valve positioned immediately where the gas pipe exits the bottle locker. The latter are ignition-protected and can be activated from a switch below decks, which ensures that gas build-up from a leak between the bottle and any manual valve beside the cooker is prevented.

Check all connections regularly

It is also handy for shutting the gas off without going outside. Note, a ‘latching’ type gas shut-off valve will consume around a third of the power when active than a non-latching variant.

Cooking and heating

The most common gas appliance found on a boat is a cooker. Sometimes you also find gas hot air heaters, such as the Propex models, and sometimes water heaters or old 3-way fridges. The latter two are now rare on sea-going boats, thankfully, as they usually require an external flue, which is almost impossible to make watertight.

Modern cookers should all have flame failure devices fitted. These are thermocouples positioned in the flame that keep the gas valve open provided it always detects the heat of the flame. If the flame should go out it shuts off the gas supply locally, eliminating the risk of gas build-up escaping in a draught.

Cookers are a main culprit when it comes to gas leaks, so ensure your crew know how to use yours safely

Gas heating in boats is relatively rare, although hot-air blowers such as the Propex range, which are designed for trucks and vehicles, are fine if installed correctly using marinised parts.

Diesel-fired heating systems, made by the likes of Eberspächer, Webasto, Wallas and Autoterm, are by far the most common in boats and much safer than using LPG. Cheap Chinese-made diesel heaters are everywhere online, but care needs to be taken when installing and often expensive marinisation needs to be carried out to make them safe for use on a boat, particularly the exhaust system.

On-demand gas water heaters are only used in houseboats and inland watercraft these days. They are rarely found in modern sea-going craft, where water is usually heated via the engine heat exchanger and a calorifier.

Flame-failure detectors have greatly reduced the risk of gas leaks

Silent killer

The problem with any form of gas heater when used in an enclosed space is the risk of a lethal build-up of carbon monoxide (CO), which is a silent killer that takes many lives every year.

The fumes tend to come from portable gas cookers designed for external use that are moved inside in poor weather to cook on or to provide heat. CO fumes can also be created by poorly maintained cooker rings, which can be signalled by yellow-coloured flames.

Another less lethal by-product of burning gas inside is prolific condensation, which can make life on board unhealthy and unpleasant.

To conclude, never run open flame gas devices below decks without ensuring adequate ventilation is available, and always fit at least one CO alarm as well as an LPG detector.

Modern hot air blowers are safe and effective if fitted properly

Gas safety routine

Like many aspects of running a yacht, it’s a good idea to create a procedure for gas safety that all on board can learn and abide by. Some even put such details up on a notice where it can be clearly seen, such as inside the gas locker lid or by the cooker. Even if you have manual and remotely switched shut-off valves fitted, it is still safer to turn the gas off at the bottle when not in use.

No valve can prevent a leak from a dodgy regulator. Should you suspect a leak, alert everyone on board and get them all off quickly. Ensure the gas is turned off at the bottle and do not turn anything electrical on or off as even a small spark could ignite any gas. Open all hatches wide and lift up the sole boards wherever possible to allow good air flow through the boat, then manually pump out the bilges if you can.

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

YM is packed with information to help you get the most from your time on the water.

-

-

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

-

Follow us on Facebook, Twitter and Instagram.