Woven or laminate? That’s the choice for anyone in the market for cruising sails – until now. Chris Beeson finds out how North Sails has blown the debate wide open with NORDAC

NORDAC – a new way to make cruising sails

As with most things in life, choosing new cruising sails involves compromise. You can opt for the longer life and lower cost of woven polyester sails and accept that, within a season, they will begin to stretch and you will lose full control because you can’t flatten the sails, which means more heeling, more weather helm, more leeway.

With a woven sail, stretch is inevitable, even if you ease halyard and outhaul after use

There are more expensive sailcloths that weave in stretch-resistant fibres like Dyneema and Vectran, but the very fact that they are woven means they will still stretch as the fibres straighten under load. Woven polyester sails are by definition low modulus (resistance to stretch), low tenacity (breaking strength) compared to newer fibres, but remain popular because of their comparatively low cost, high UV resistance and high flex resistance, which means they can take a lot of punishment.

In the early 1980s, another option became available: the paneled laminate sail, which is lighter aloft, holds its shape very well and will deliver better sail control, but costs more, is prone to mildew and is more fragile. Its shape-holding ability is delivered by a ‘scrim’ or mesh of polyester or higher-tech yarns like aramid, Dyneema or carbon fibre, sealed onto a thin film, usually Mylar. For cruising purposes, this is then covered on both sides with tafetta to protect the film and scrim. The scrim is built with straight fibres so stretch is greatly reduced compared to a woven cloth. However, once the Mylar film or the scrim is damaged, the sail loses its strength and sooner or later it will fail in a spectacular and expensive way.

Now there is a third option. In the search for performance advantage, racers demand innovation from sail lofts, sail designers and scientists. Since time immemorial, sails have been made from panels of cloth sewn together. That was still the case in 1955 when DuPont released Dacron, a woven polyester sailcloth that replaced cotton canvas as the cloth of choice. The cloth is still cut into panels and sewn together in the time-honoured fashion, but compared to cotton, Dacron was stronger, lighter and had better UV resistance.

3Di are the sails of choice for most round the world racing yachts, and the records keep falling

In 1992 North Sails introduced 3DL sails. The big breakthrough was that the sail was laid up on a mould, built in three dimensions rather than two, so its shape could be controlled perfectly. Also, it enabled the use of continuous fibres along the loadpaths, rather than the discontinuous fibres you get if you stitch panels together. The result was perfect shape, hardly any stretch and light weight. The only drawback was that 3DL was a laminate sail, hence fragile. The challenge was: can we build a moulded sail without using Mylar film?

The breakthrough came when Swiss engineers working for Alinghi’s 2007 America’s Cup challenge laid out fibres and pre-impregnated them with thermoset resin glue, creating featherweight filament spread tapes of pure fibre. By building these into sail sections, adding extra layers of tape in high stress areas where strengthening is needed, then vacuuming these onto the mould, heat treating to activate the resin glue, a one-piece sail was created that was pure fibre and, crucially, no film. In the end Alinghi didn’t use the shiny, jet black sails but North Sails understood the potential of the technology, then known as Amalgam, bought it and used it to launch its 3Di range of sails.

If you follow ocean racing, you’ll be familiar with 3Di sails. They are used by most of the boats in the Vendée Globe, and all of the boats in the Volvo Ocean Race. They were also used by Thomas Coville aboard his 31m trimaran Sodebo Ultim when he sailed solo around the world in under 50 days, and on the 31.5m trimaran Idec Sport when Francis Joyon and his crew of five sailed around the world in under 41 days. Reliability is not an issue for 3Di. The technology is well proven.

The big news, the breakthrough, is that North Sails has adapted this technology to process polyester fibres. The result is 3Di NORDAC, a sail that is 100 per cent polyester, the fibres and the resin, which has all the durability characteristics of a polyester sail, high UV resistance and high flex resistance, but holds its shape because it’s been built with tapes made from straight fibres, not woven ones. Also because it’s polyester, it’s low cost. Surely this is too good to be true?

What is different about the production process?

Process for woven polyester

Dacron is woven from fibres to make cloth as part of a multi-stage production process

1 Fibres created

2 Fibres transported to weaving mill

3 Fibres coated with sizing to improve the weaving process

4 Fibres woven into greige goods

5 Greige goods transferred to finishing plant

6 Greige goods scoured to remove sizing, then dried

7 Greige goods impregnated with resin and heat shrunk

8 Woven cloth calendared with high pressure rolling

9 Finished sailcloth transferred to distribution warehouse

10 Finished sailcloth transported to sail production facility

11 Finished sailcloth is cut into panels

12 Panels are assembled and sewn into blank sail

13 Blank sail fitted with ropes, rings and tapes and patches

14 Finished sail is transported to customer

Process for 3Di NORDAC

3Di sails are built from tapes of pure fibre

1 Fibres created

2 Fibres transported directly to sail production facility

3 Fibres converted to resin-impregnated filament spread tapes

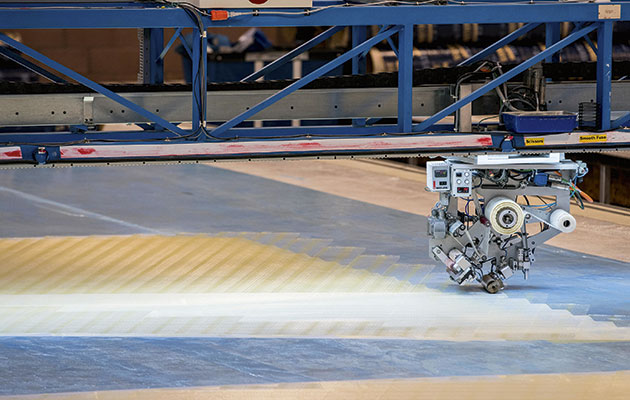

4 Filament tapes are robotically assembled into sail sections

5 Sail sections are vacuum-moulded and cured into a monolithic sail membrane

6 Sail membrane fitted with ropes, rings and tapes

7 Finished sail is transported to customer

What’s the truth about 3Di NORDAC?

North Sails says 3Di NORDAC is as big a sailmaking revolution as the introduction of Dacron in 1955

To find out more, we spoke to North Sails’ Bill Fortenberry (left) and Sam Richmond

It sounded like snake oil to us too, so we spoke to Bill Fortenberry, North Sails’ cruising market manager, and Sam Richmond, an expert from North Sails UK, to find out the facts.

Up close it’s possible to see the straight polyester fibres and the orientation of the spread tapes

Was there a big breakthrough, or was this a logical extension of the 3Di process?

BF: Both. 3Di has been evolving for 6-8 years, but no-one was thinking of a polyester product. We want to better serve all the market segments and the cruising market is an opportunity for us. How could we help with better sails and better durability? Then a light bulb went on: could we build a white polyester sail in our 3Di process?

It took 18 months to figure out how to handle polyester fibres, these micro-thin filaments of polyester, in the 3Di process. Polyester is stretchier, which is a benefit as it makes the sail tough and more forgiving, but when you pull it though a machine to make the filament spread tapes, that needs tension so it wants to recoil when the tension is relaxed. Making the tapes was the hard part.

3Di NORDAC blends modern construction and traditional fibres. Rather than weaving, we’re spreading. Rather than stitching, we’re glueing.

Fibres, Aramid in this case, are impregnated with resin and rolled onto paper for storage

How many layers of tape are needed, and how are the layers glued together?

BF: There’s a minimum of six up to a maximum of 300 layers, on the clew of a superyacht main, say. You make 3Di NORDAC in the same way you’d build a boat on a male mould, with extra structural strengthening where it’s needed.

We use a thermoset two-part polyester resin. The heat lamp gets the resin to flow, the catalyst sets it. It can’t be melted if you heat it.

Next the fibres are robotically laid into sail sections according to computer models

It’s a seamless sail, so what are the lines that look like seams, the square pattern?

BF: The top two to three layers of tapes on both sides are external protective tapes, running horizontal and vertical, which provide chafe abrasion and UV durability. The outer tapes overlap slightly and that is creating the square pattern.

Are the reefs’ tacks, clews and feet beefed up with patches?

SR: Reefs are traditionally added as an afterthought. Here we get to lay it up as we’re building the sail, so there is no extra weight where it doesn’t need to be.

Are UV strips, webbing tapes and rings stitched in as usual?

BF: Tapes and rings are stitched in. We’re still experimenting with the UV strip. It could be stitched, or painted on. These sails have additional external tapes built in, not stitched. That’s not standard, it’s something we’re looking at.

Are there any specific care requirements for 3Di NORDAC?

SR: No, you can wash it like you would any Dacron sail.

BF: If you poked a hole through the sail you can patch, glue or stitch it back together. Mildew is less of an issue as there are no voids for water to get into.

These sections are then vacuumed onto a mould and heated to activate the resin that glues it into a single sail

What are the advantages/disadvantages of 3Di NORDAC over standard Dacron?

SR: I can’t come up with a single disadvantage. You’re paying similar money for a polyester sail to get a one-piece moulded sail, which is more durable and less stretchy than anything before, and it feels way nicer than Dacron in the hand.

BF: It’s a better cruising experience and the North Sails customer enjoys sailing. We’re often accused of being too performance oriented but cruising performance is a thing. It involves moving through the water more effectively and efficiently. That means ease of handling, ease of trim and better shape holding because you want less weather helm, less leeway, less heel. Less stretch means more control. Cruising performance also means durability, and 3Di sails are proven to last.

Finally rings and tapes are stitched on by hand and the sail is ready for delivery

Without seams, will these sails be lighter that similar panel sails?

BF: It should weigh the same as a crosscut Dacron sail, but with more strength and toughness. It could be lighter for the same strength as a crosscut sail. The stiffness that comes with 3Di sails makes furling easier, stacking on the boom is a little different at first. The additional strength is built into the structure, with many layers of tape at the corners and reef points. Even the batten pockets are built in. The pockets are closed at the leech, the batten slides in from the luff.

Have you had any failures yet and, if so, what was learned?

BF: Yes, we had some luff slides tear out. We’ve made about 50 3Di NORDAC sails and those would have been in the teens. Where slides attach to sails, we use grommets and webbing straps. We learned we needed to build up the fibre mass more than we expected where the slides attach so we built up the structure in that area.

The result is a one-piece sail built to hold its shape with less stretch than any woven sail

For potential customers, how are you backing up your faith in 3Di NORDAC?

BF: All North Sails have a one-year warranty on defects in quality or workmanship, and a year’s free sail care. Depending on use and care, we guarantee the structure of the sail beyond that. Cruisers expect sails to last 6-8 years or more and 3Di NORDAC is engineered accordingly.

The square pattern is due to horizontal and vertical layers of protective outer tapes, to prevent chafe and resist UV

Why are you sending out measurers to everyone who orders a sail? Aren’t those measurements already known?

BF: Every 3Di sail is a custom sail. There is a base aerodynamic model but the aspect ratio and size is different so the mould on which the sail is laid up changes for every single sail. No two boats are the same. It’s the same service any raceboat would get.

It sounds expensive. Will cruising sailors be able to afford them?

BF: North Sails is a premium quality brand. We have never been the least expensive sailmaker but we are pricing 3Di NORDAC within our existing Dacron product family to be affordable on small and medium-sized boats. Customers will be pleased with price and value. The racing guys tend to occupy the moulds in racing season, so you’ll get a better deal if you order outside the first half of the year.