Which is the best folding or feathering propeller for your boat? Emrhys Barrell compares 15 props in a test of speed, thrust, drag, stopping speed and propwalk

Folding and feathering propeller test

What’s the difference between a bucket and a fixed, three-bladed propeller? Not much, if you want to slow your boat down by at least half a knot when you are sailing. That’s the conclusion of our fixed, folding and feathering propeller test – the most detailed ever conducted as far as we are aware. A fixed three-bladed prop, locked in gear, exerts as much drag as hanging a bucket over the stern.

So what is the solution if you don’t want to sacrifice precious speed? The answer is, fit one of the many folding or feathering props on the market. But which one, and what are the drawbacks?

We tested all the props we could get our hands on (except the Volvo, Radice and J-Prop, which turned up too late for the test), measuring top speed under power, thrust (bollard pull) ahead and astern, stopping distance, and – for the first time anywhere – we measured the side-force (propwalk) generated when you put the engine into reverse.

It is this vital, unwanted component that sends you swinging off to one side when you try to stop suddenly, or back-up in the marina. We then towed three typical props behind a test boat to measure their drag, and how it compares to the overall drag of a yacht under sail.

Prop drag has been an issue for sailing vessels since the propeller was invented. Early trials were carried out on English warships, using jointed shafts that could be lifted into a trunk in the hull when sailing. In the 1890s, Danish pilot boats used similar lifting shafts.

For many years, long keels reduced the drag of two-bladed props on yachts, but the advent of the fin keel and exposed shafts brought the problem back again, with the added factor of more powerful engines making three-bladed props a necessity. The need to manoeuvre precisely in tightly packed marinas and overcrowded harbours has convinced even the owners of many long-keeled yachts to fit three-bladed props.

1970s: the first folding props

Most cruising skippers simply ignored the unwanted drag and loss of speed, but in racing circles it became increasingly significant. This led to the development in the 1960s and 70s of propellers whose blades folded backwards when sailing, reducing the drag markedly. The blades flew out under centrifugal force when the engine was put into ahead or astern. The earliest folding props had blades that moved independently, but this could lead to the lower blade dropping down when sailing, so the roots of the blades were linked with geared teeth, ensuring that they opened and closed together.

At the same time, an alternative approach was developed: the feathering propeller. Here, the blades were set at right-angles to the boss, as in a conventional prop, but on swivelling hubs. When motoring, the blades swing to the ahead or astern angled position, but under sail they ‘feather’, turning parallel to the boss.

One great advantage of feathering props is that they’re suitable for the many fin-and-skeg and long-keel yachts that have a small prop aperture in the rudder, where a folding prop won’t fit.

In the earliest feathering props, the blades remain in the same orientation to the boss in ahead or astern, as with a conventional fixed blade prop. In astern the aerofoil is working backwards, giving less thrust than in ahead. Some new feathering props have blades that swing right round, so the same leading edge is presented to the water in ahead or astern.

Cut prop drag by 90-95%

Under sail, the drag of folding and feathering props is tiny compared to a standard fixed-blade unit. Feathering props create about 5-10% of a fixed prop’s drag, sometimes less, while folding props have almost zero drag. This gives a significant gain in sailing speed, between half a knot and one knot, with the greatest percentage saving at low speeds.

Inevitably, there are drawbacks. The first is expense: a folding or feathering prop costs between two and six times more than a fixed equivalent. The second issue is complication – the gearing and folding mechanisms are prone to wear and corrosion in the salty and sandy environment, leading to reduced performance, and even loss of blades in extreme circumstances.

The third problem was performance under power. The early folding and feathering props produced less thrust than an equivalent fixed prop, particularly in astern, with dire consequences if the blades fail to deploy when you need to make a crash stop.

Now, the manufacturers claim to have addressed all the issues except cost. They claim the latest generation of their products give as good a performance or better under power, and major gains in speed under sail. We put their claims to the test on two chilly days in February. To our folding and feathering props we added a fixed three-blade prop as a benchmark, and the Axiom prop, a radical new development in fixed propellers, just to see how it compared.

Prop facts

To help you understand our test, we will take a quick look at propeller theory and numbers. The four main figures you will see used to describe any prop are diameter, pitch, number of blades, and rotation.

Diameter is twice the distance from the centre of the boss to the tip of the blade. As a rule of thumb, the more powerful your engine, the bigger the diameter you will need.

Pitch is the measure of how far the propeller will advance in one revolution and thus how fast it will push your boat through the water for a given engine rpm (revolutions per minute). To understand pitch, imagine screwing a screw into a block of wood. The angle of the spiral thread governs how far it goes in for each turn. Similarly, the blades of a prop are set at an angle to the boss. The greater the angle, the greater the pitch. However, this is only the theoretical pitch. In practice, as water is not solid, the prop will slip to a degree and not advance so far. The amount of slip is around 30% for the props and speeds we are looking at.

Diameter and pitch are still measured in inches throughout the world – a quirk of history that would delight Henry VIII, and have Napoleon turning in his grave. But pitch can also be measured in degrees, especially relevant with feathering props whose blade angle can be varied.

The number of blades will vary between two, three or four, or even five in some high-speed craft. In practice, more blades will take greater power for a given diameter. For many years sailing boats used two-bladed props as they gave least drag in a boat with a full-length keel and an aperture for the prop, provided it could be locked in the vertical position. Today, most fixed props have three blades. Folding or feathering props have either two for cheapness, or three for higher power.

The hand of the propeller is the direction of rotation in ahead, when you are looking from astern. A right hand prop is one that turns clockwise in ahead.

Blade Area Ratio (BAR), sometimes called Disc Area Ratio, (DAR) is the area of the blades as a percentage of the area of a circle the same diameter as the prop. A prop with a greater BAR will take more power, but have more drag. Figures for sailing boat props are around 60%.

Incidentally, the explanation that a propeller advances just because its blades are angled forward is a convenient way to imagine what is happening, but not strictly correct. The blades of a standard prop are in fact aerofoil in section, like the wing of a plane, and move the boat forwards because as they spin round they develop lift. This lift is caused by a reduction in pressure on the back of the blade (‘back’ being confusingly the blade’s forward face). The faster they go, the greater the reduction in pressure. Once a certain point is reached, the reduction in pressure causes the water next to the blade to vapourise, and form bubbles. This is called cavitation, and limits the amount of power that a given area of blade can cope with. Also, as the bubbles collapse, they erode the metal of the prop, resulting in surface pitting on the back of the blade.

The test

We used a Bénéteau Oceanis 323, kindly leant to us by Sailtime in Lymington. She has a typical fin keel form, but atypically she has a built-in skeg carrying the shaft, rather than the P-bracket or saildrive of most other modern yachts. The skeg protects the shaft and prop from underwater damage, but a downside is increased vibration as the blades of the prop pass through the disturbed waterflow behind the skeg. This is resolved in normal use by fitting a three-bladed prop as standard rather than two, but otherwise did not alter the propulsive element of our test for either two- or three-bladed units.

The engine was a Yanmar YM20, giving 21hp at a maximum 3600rpm. The gearbox ratio is 2.6:1 in ahead, but somewhat confusingly a higher ratio of 3:1 in reverse. This is a very common engine/gearbox combination, so not an unreasonable test. Yanmar says it gives better thrust in astern, but in practice it meant the folding props were forced to use a compromise pitch. Some of the feathering props were able to set a different astern pitch.

We measured thrust, or ‘bollard pull’, in ahead and astern, throughout the rev range, using a load-cell borrowed from Diverse Yachts, with a remote read-out.

We then measured the side-thrust at full power in astern. This enabled us to predict the prop-walk created when you go into astern. To put this figure into context, the thrust produced by the worst prop in our test is the same as a 3hp outboard mounted on the transom, driving at right-angles at full throttle. No wonder so many yachts veer off to one side!

On the water, we measured speed through the rev range to maximum. We then carried out a crash stop from 6 knots. We recorded the time it took to bring the boat to rest at full throttle from the moment we engaged reverse gear.

To put these times into context, the distance the boat would travel before stopping would be 12m (39ft) with the best prop tested, but 17.4m (57ft) with the worst.

To measure the drag of all 18 propellers precisely enough to compare them with one another, making allowances for different yacht hull forms, we would have had to build a sophisticated testing rig, hire a team of scientists and spend several days in a research laboratory with a very large towing tank. Our objective was just to demonstrate the difference in drag caused by different types of propeller.

We fitted a fixed prop, then a folding one, then a feathering one, to an outboard motor leg mounted on the transom of a lightweight 14ft skiff. We then towed the skiff at speeds up to 7 knots, and measured the difference in drag. We don’t claim this gave us the last degree of accuracy, but it was sufficient to compare with published drag figures. We then compared this drag to the hull-only drag of the Océanis 323 – a typical 10m cruising yacht.

A question of some gravity, Mr Newton

To keep things simple, we have presented our drag and thrust figures in kilograms (kg). Strictly speaking, thrust is a force and should be measured in Newtons – 1kg is multiplied by the acceleration due to gravity to give a figure of 9.81N. On another planet, with different gravity, our units would be wrong, but until we hear they are holding regattas on the canals of Mars, we will rest our case.

The results

Featherstream three-blade

Made in England at the time of writing (2009), this is a three-blade feathering unit with a bronze boss, and stainless steel blades. The pitch of the blades can be adjusted externally, and can be different for ahead and astern. The blades swivel 180º to present the same leading edge in ahead and astern. As a result, it performed well in astern: second best for bollard pull and third for stopping distance. However, occasionally it would not open in astern, and you had to learn to snap the throttle hard to get it to deploy.

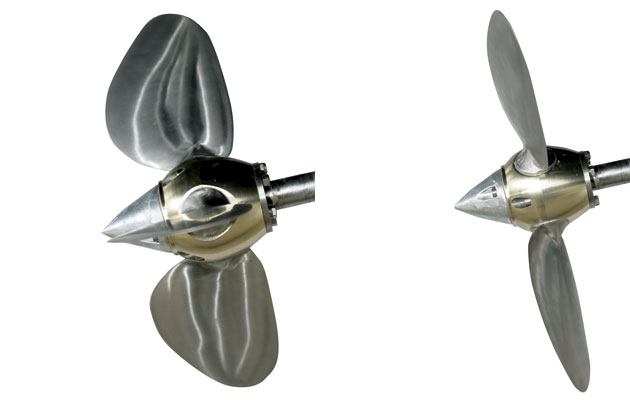

Max Prop three-blade

Designed by Massimiliano Bianchi in 1976, the Max Prop was one of the first of the new generation of props. Boss and blades are bronze, and the pitch can be set as you assemble it, or by the factory if you want a different astern pitch. The blades swivel 180º to present the same leading edge in ahead and astern. It gave the best astern thrust, and was in the middle of the pack for stopping distance. It never missed a beat going into astern.

Max Prop two-blade

A two-blade version of the Max prop. As expected, it gave some vibration on our test boat, but this would not occur on a yacht with a P-bracket or saildrive. Mid-range performance for astern thrust and stopping distance.

Kiwi Prop three-blade

Designed in New Zealand in 2000, this is only available as a three-blade unit. The boss is stainless steel, and the blades are glass-reinforced Zytel plastic. Each blade has two different aerofoil sections, as you move out from the boss. It has no internal gears, so each blade feathers independently according to the waterflow over it. The blades do not swing completely round in reverse, so the trailing edge becomes the leading edge. It was one of the simplest to fit – just slide it on and tighten the nut. Mid-range for astern thrust and stopping distance, but the lowest top speed. It also went easily into astern.

Autoprop

Brunton’s Autoprop marked a completely different approach to feathering props when it was brought out in 1987. The three blades are linked together, going from fully feathered while sailing, or in neutral, to fully twisted under power. The difference is that when you go into gear, the amount they rotate depends on engine speed and loading. Thus the ahead or astern pitch varies according to engine rpm, which, Brunton claims, improves performance and fuel economy, with reduced rpm for a given cruising speed. We can confirm the latter: our tests show the Autoprop achieved 6 knots at 2,100rpm, compared to 2,500rpm for our standard prop and most of the others on test. However, previous drag tests have shown that this is achieved at the expense of slightly more drag than other feathering props, though still 80% less than a fixed prop. Bollard pulls were on the low side, but it still achieved near the maximum top speed, with mid-range stopping distance.

Autostream three-blade

From Australia comes the Autostream, a three-bladed feathering unit that has been in production for 20 years. Construction is all-stainless steel, with the blades swivelling 180º to give the same leading edge in astern as ahead. Separate ahead and astern pitch can be adjusted by the owner without dismantling the prop. It has been designed to stay feathered at speeds up to 25 knots, helped by extra blade area aft, making it suitable for fast multihulls. On test, it gave the fastest stopping time of all the folding or feathering units, plus significantly lower side-thrust than the rest, while still maintaining good ahead speed.

Variprofile three-blade

This is a three-blade feathering prop, made in Germany. The blades swivel 180º to give the same leading edge in astern, and the pitch can be set differently for ahead and astern. Usually, this is set in advance for the customer, but can be altered on site. Blades and boss are bronze, with stainless pins, and an anode aft of the nut. Ahead thrust was low, but stopping distance was good.

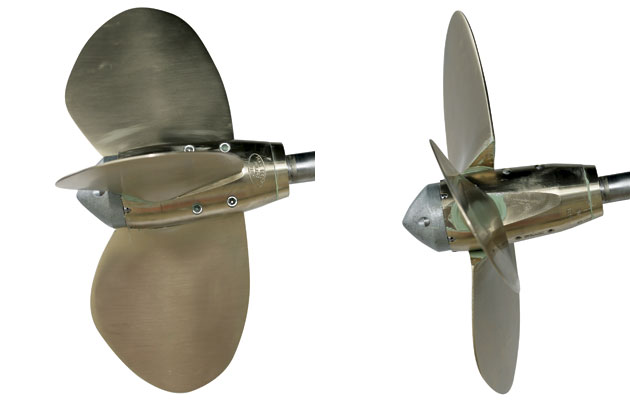

Flexofold three-blade

Made in Denmark at the time of writing (2009), the Flexofold is an all-bronze folding unit, with stainless steel pins, and the anode cleverly enclosed by the blades. On test, it gave the equal highest forward thrust of all props, and highest top speed. It also had one of the lowest side-thrusts. Astern performance was the best of the folding props. At a cruising speed of 6 knots, the engine was turning at 2,300rpm, compared to the 2,500rpm of our standard fixed prop and most of the others on test.

Flexofold two-blade

A two-blade version of the Flexofold, its performance was only slightly down on the three-blade, and in fact better for astern thrust. Again, it had some vibration due to the skeg. A racing two-blade version is also available.

Gori three-blade

Another of the earliest folding designs, the Gori has been made in Denmark since 1975, in two and three-blade versions, but the company only recommended the three-blade for this boat. They also make a racing two-blade version, with reduced drag. The blades have a three-way gearing system for opening and closing. Boss and blades are bronze, with stainless steel pins. A speciality is its overdrive feature, which sets the blades in a coarser pitch if you open the throttle gradually while the boat has forward way on, which allows you to cruise or motorsail at lower rpm for more comfort. Performance ahead and astern were towards the bottom of our list, with the longest stopping distance, but the prop-walk was third best.

Slipstream three-blade

From the same Australian company as the Autostream comes the Slipstream folding prop. Again the boss and blades are stainless steel, which gives greater strength, allows thinner section blades, and removes the need for an anode. The bearings are bronze bushes, while the blade gears are bevelled, with two rows each, claimed to better chew up any barnacles that might chose to grow on them. Polyethylene side thrust washers further improve the opening action. On test it performed in the middle of the folding props, though with comfortable low cruising revs of 2,250rpm at 6 knots.

Slipstream two-blade

Similar in design to the three-blade version, though with slightly worse astern figures, but it still made 6 knots at a low cruising rpm of 2,350.

Varifold two-blade

Made in the UK, this is mid-way between a racing and cruising prop, with the blades closing tightly for low drag, but still having enough shape to give good motoring performance. As a result of its close fit, you have to give the engine a burst of throttle to get the blades to open initially. It has a bronze boss and blades, and stainless steel pins. It gave equal highest top speed, but was near the bottom of astern performance.

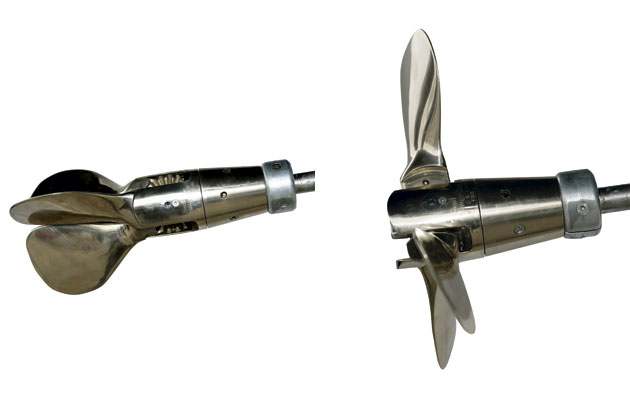

Axiom three-blade

The Axiom is the joker in our pack. It is not a folding propeller, but it does have a revolutionary blade profile and section, if you will pardon the pun, and has never been tested on a yacht before, so we just had to put it into our trials to see how it compared. As the photograph shows, the blade profile is rectangular, while the blade section is almost S-shaped, and symmetrical in ahead and astern, with no twist. Its designers claim it gives greater thrust and stopping power, together with lower wash. So how did it stand up? Well the charts show the story, with its stopping time nearly a second better than any other model, and its side thrust again the lowest by far. However this was at the expense of lower top speed, which suggests some more tweaking is needed, but it is still one to watch.

Drag curves

In the graph above, you can see that at 5 knots, a fixed three-blade prop with its shaft locked creates almost half as much drag as the entire hull. The drag can be halved by allowing the prop to spin, but the gearbox may suffer. By contrast, the drag of a feathering prop is negligible, and the drag of a folding prop is too small to plot on a graph of this scale.

The hull resistance curve for the Océanis 323 was calculated for YM by the Wolfson Unit, at the University of Southampton, using data from the Delft University Systematic Series. The propeller drag curves are based on data from SSPA Maritime Consulting, using Volvo S-drives. This data were verified by YM’s on-the-water drag test.

Propwalk

All but three of the propellers on test produced less prop walk than the standard fixed prop. The fixed Axiom and feathering Autostream were the best performers, but nearly all the folding props fared better than the rest of the feathering propellers.

Maximum speed

There was more than half a knot of difference between the best-performing props and the worst. Four folding propellers and one feathering prop managed to prove the claim of better performance than a standard fixed prop, but nine of them fell slightly short.

Interestingly, some of the best performers were two-bladed props, which are widely assumed to perform worse than three-blade versions.

Bollard pull ahead

The fastest props are generally also the most powerful in ahead, and most of the slower ones are among the least powerful. However, only one unit – the three-bladed Flexofold – generated a greater bollard pull than the standard fixed prop. The most powerful props produce almost a third more thrust than some of their rivals.

Bollard pull astern

Three propellers produced a more powerful bollard pull than the standard fixed prop in astern: two folding units and the newly designed Axiom. Nearly all the feathering props performed better in astern than the folding ones – some by a very wide margin. There’s a huge difference between the best and worst-performing props – the three-blade Max Prop has almost twice the bollard pull of the two-blade Varifold.

Stopping time

The new-concept Axiom prop excelled in this test, but nearly all the feathering props were better at bringing the boat to a standstill than the standard prop. The folding props were less effective and some of them were less than 100% reliable when called upon to perform an emergency stop. The difference between the best and worst stoppers was about 3½ seconds. It may not sound like much, but in a crunch, it could make all the difference.

Conclusion

If you want to add up to a knot to your boat speed, then fitting a folding or feathering propeller is a must, not just for racing boats. And as our test demonstrates, you can usually still retain the handling and performance under power that you had with a standard fixed-blade prop. In fact, often you’ll get better performance.

Five of the tested props gave more speed than the standard prop, with four of them being folding models, and both Flexofolds coming out top. And even though it was only 0.15 knots better, when you look at the hull resistance curve this is a considerable improvement. On the other hand, with astern performance, in general it was the feathering props that came out best, with better bollard pull than the standard, and better stopping times, and the Autostream coming out top. The folding props were generally not as good as the standard, though in the main only by no more than 10%.

But it was the prop-walk figures that proved the most interesting. Ten of our test units gave less prop-walk, with generally the folders coming out best, but the top units being the Axiom and Autostream, with 30% less side-thrust than the standard fixed three-blade, a considerable advantage when you have to stop suddenly or back-up in a marina.

In terms of resistance, our test shows that letting your fixed-blade prop spin, if the gearbox manufacturer will allow it, halves the drag. But to get the real improvement, fitting a folding prop will give at least 95% less drag than a locked, fixed propeller, while a feathering unit will give at least 92% of the drag – still an enormous saving.

But these benefits do have a price, literally on your wallet. A 16in fixed three-blade propeller will cost around £300 (2009 prices in UK). But the cheapest two-blade folding prop will be at least double this price, with most of them between £600-900. For a three-bladed folding unit expect to pay between £1,200 and £1,600. Feathering props are even more expensive, starting at around £1,200 for a two-blade model, rising to £2,100 for the most expensive three-blade version.

Because of the wide variation in cost, performance and specifications of the all the units tested, we have not felt it appropriate to recommend a best buy. The tables and curves give you the information you need at a glance, allowing you to make your own decisions as to which is best for you and your boat.

Prop tips

Fitting

Some are easy to fit, others difficult. Professional installation is advised for such an important – and expensive – bit of kit

Some of the props on test are very simple to install, others are very complicated. However, while they all have instructions for DIY fitting, unless you’re very confident in your own skills, a piece of equipment as vital as a propeller ought to be professionally installed, both for safety and peace of mind. For our test, we had every prop fitted by the manufacturer’s representative, so there was no question about the installation, and they also observed all our measurements.

Materials

Bronze has been the material of choice for propellers almost since they were invented. Strong, resistant to salt-water corrosion, it is also easy to cast, with a low melting point, as our ancestors found out 4,000 years ago. Stainless steel has been making an appearance recently. Even stronger, it allows thinner and so more efficient blades. It is even more corrosion resistant, and also harder, so less vulnerable to impact damage. However, it has a much higher melting point, so it is more difficult and expensive to cast and machine.

Maintenance

Whatever prop you have, it should be checked every time the boat is lifted, for wear, corrosion and movement. Folding and feathering props do require more maintenance than fixed ones. Some bosses are packed with grease, which should be repacked annually. Some have nylon shims or bearings, which should be checked, especially in silted waters. Most have an anode, which should be checked and replaced if necessary.

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook, Twitter and Instagram.